Post-construction cleaning in Seattle presents unique challenges and safety risks. At Bumble Bee Cleaning Services, we understand the importance of construction site safety during these crucial cleanup operations.

This guide will explore the potential hazards, essential safety equipment, and best practices for ensuring a safe post-construction cleaning process. By following these guidelines, cleaning crews can protect themselves while effectively restoring construction sites to their pristine condition.

What Are the Risks in Post-Construction Cleaning?

Physical Hazards on Construction Sites

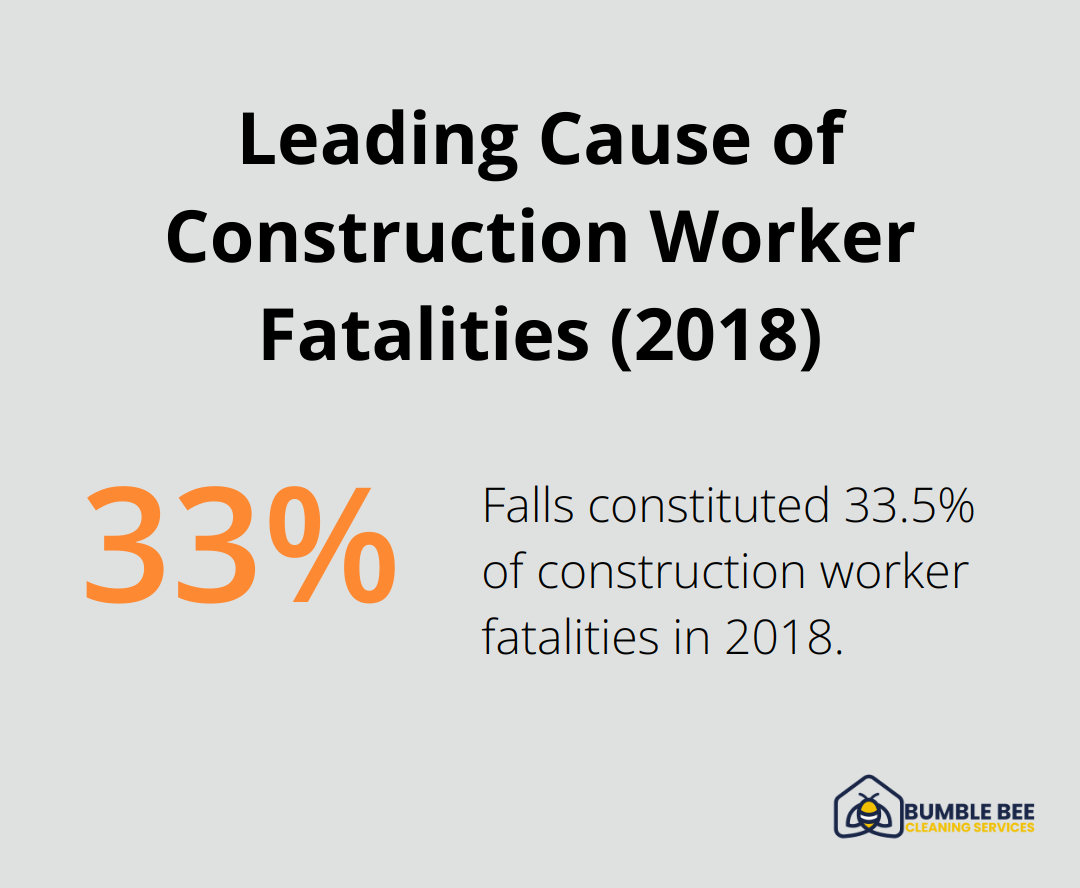

Post-construction cleaning involves numerous physical hazards. Sharp objects pose risks of cuts and puncture wounds. Uneven surfaces and scattered debris increase the likelihood of trips and falls. The Occupational Safety and Health Administration (OSHA) reports that falls constitute the leading cause of death in construction, accounting for 33.5% of construction worker fatalities in 2018.

Exposure to Harmful Substances

Construction sites often harbor hazardous materials that threaten health. Silica dust, a common byproduct of concrete work, can cause silicosis, a potentially fatal lung disease. Exposure to these materials can lead to serious health conditions such as lung cancer and chronic obstructive pulmonary disease (COPD).

Other dangerous substances include asbestos from older buildings, lead paint, and various chemical residues. Prolonged exposure to these materials can result in respiratory issues, skin irritations, and even cancer.

Ergonomic Challenges

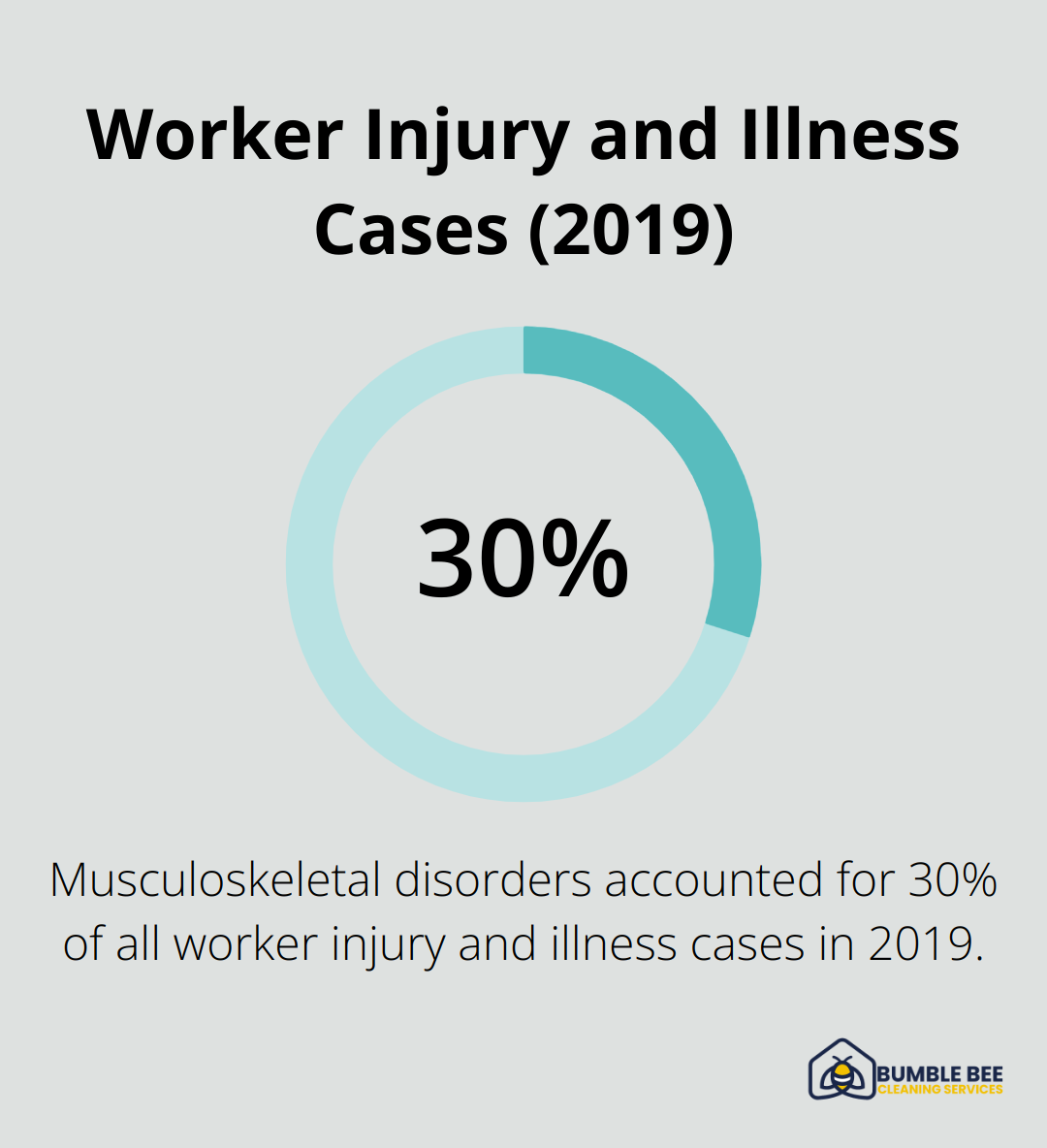

The physical nature of post-construction cleaning strains the body. Repetitive motions, heavy lifting, and awkward postures can lead to musculoskeletal disorders. According to the Bureau of Labor Statistics, musculoskeletal disorders accounted for 30% of all worker injury and illness cases in 2019.

Electrical and Fire Hazards

Incomplete or damaged electrical systems in post-construction environments present risks of electric shock or fire. Exposed wires, temporary lighting setups, and power tools left on-site can all contribute to these dangers. The U.S. Fire Administration reports that electrical malfunctions cause about 6.3% of all construction site fires.

Chemical Risks

Cleaning products used in post-construction cleanup can pose their own risks. Strong solvents, acids, and other chemicals may cause skin irritation, respiratory problems, or chemical burns if not handled properly. The Environmental Protection Agency (EPA) emphasizes the importance of proper ventilation and protective equipment when using these products.

The multitude of risks associated with post-construction cleaning underscores the need for proper safety equipment. Let’s explore the essential gear that protects cleaning crews from these hazards.

What Safety Equipment Is Essential for Post-Construction Cleaning?

Post-construction cleaning requires specific safety equipment to protect workers from various hazards. Safety gear plays a vital role in mitigating risks associated with this type of cleaning.

Personal Protective Equipment (PPE)

Personal Protective Equipment forms the foundation of safety in post-construction cleaning. This guide will help you to comply with the WISHA (Washington Industrial Safety and Health Act) Personal Protective Equipment rules. Hard hats protect against falling objects, while safety glasses shield eyes from dust and debris. Steel-toed boots guard against heavy objects and sharp materials. Respirators filter out harmful particles like silica dust, and gloves protect hands from cuts, chemicals, and abrasions.

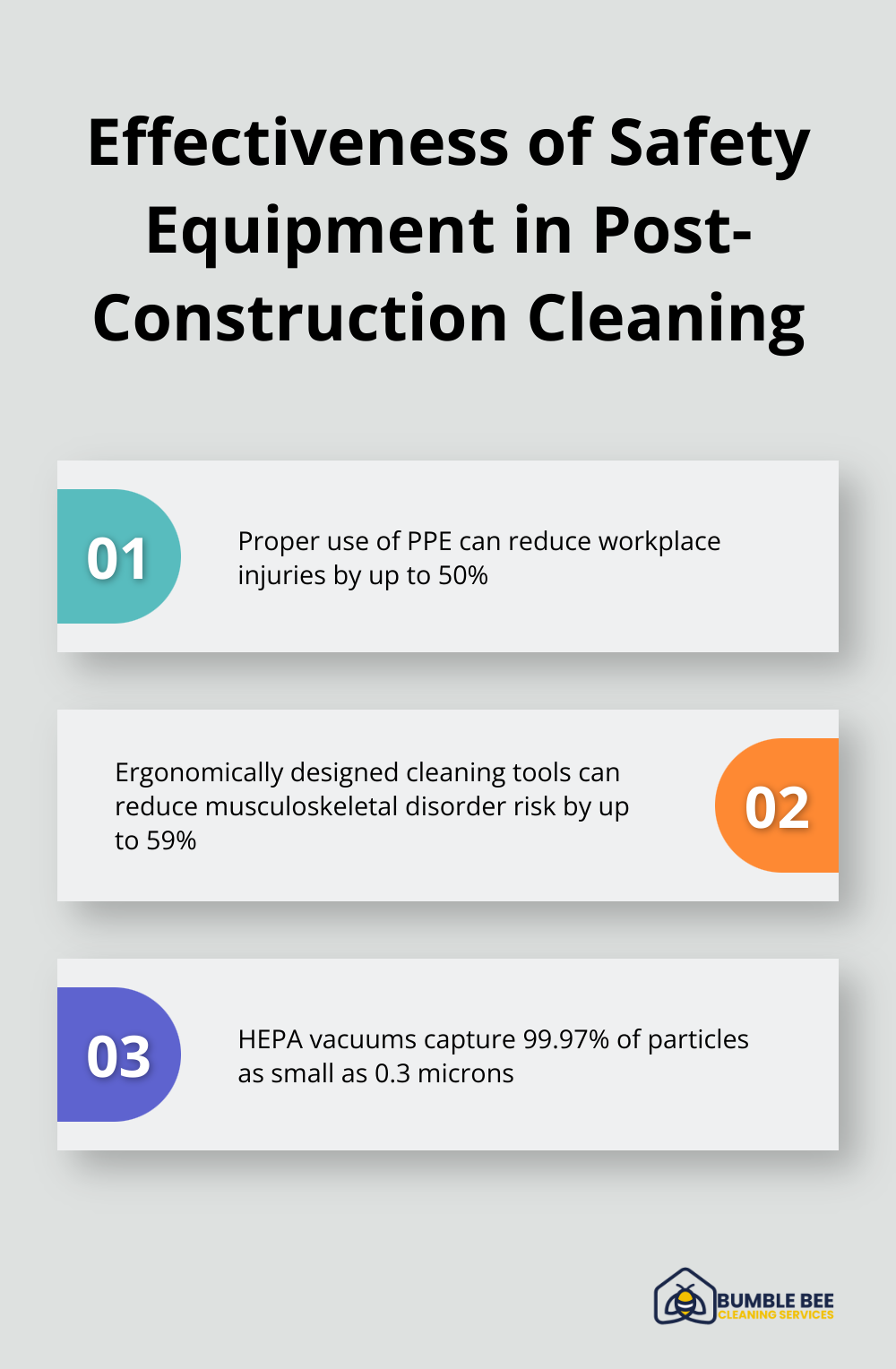

The National Institute for Occupational Safety and Health (NIOSH) reports that proper use of PPE can reduce workplace injuries by up to 50%. However, providing PPE is not enough; workers must receive training in its correct use and maintenance. The Occupational Safety and Health Administration (OSHA) requires employers to provide PPE training to all employees who use it.

Specialized Cleaning Tools

Post-construction cleaning often calls for specialized tools with built-in safety features. High-efficiency particulate air (HEPA) vacuums capture 99.97% of particles as small as 0.3 microns, which significantly reduces airborne dust and debris. Wet-dry vacuums clean up liquid spills safely, while extendable dusters and mops allow workers to clean hard-to-reach areas without overextending themselves (thus reducing the risk of falls and strains).

The American Journal of Industrial Medicine states that using ergonomically designed cleaning tools can reduce the risk of musculoskeletal disorders by up to 59%. This statistic highlights the importance of investing in quality equipment that not only cleans effectively but also prioritizes worker safety.

Chemical Safety Measures

Proper handling and storage of cleaning chemicals is paramount in post-construction cleaning. All chemicals should have clear labels and remain in their original containers. Safety Data Sheets (SDS) for each chemical must be readily available, providing critical information on proper handling, potential hazards, and first aid measures.

The Environmental Protection Agency (EPA) recommends using green cleaning products whenever possible to reduce exposure to harmful chemicals. These products offer safer alternatives for workers and the environment. When stronger chemicals become necessary, proper ventilation becomes critical. The use of fans and open windows helps disperse fumes and reduces the risk of respiratory issues.

Safety equipment forms the backbone of effective and secure post-construction cleaning. However, equipment alone does not guarantee safety. The next section will explore best practices that complement the use of safety gear to create a comprehensive safety approach in post-construction cleaning environments.

How to Execute Safe Post-Construction Cleaning

Create a Detailed Site Assessment

A thorough site assessment must precede any cleaning activities. This step identifies potential hazards and determines appropriate cleaning methods. Unanticipated hazards can arise due to sequencing changes. Workers may or may not be trained. Decisions are made which may or may not prove to be safe.

The assessment should include mapping out the cleaning sequence. Cleaning should start with higher areas and progress downwards to prevent re-contamination of cleaned spaces. This approach can reduce cleaning time while minimizing exposure to hazards.

Implement Effective Ventilation Strategies

Proper ventilation is essential in post-construction cleaning. Ventilation and air cleaning devices can reduce exposure to air pollutants that cannot be eliminated by source control. To reduce carbon monoxide build-up and other pollutants, adequate ventilation is crucial.

For enclosed spaces, air scrubbers with HEPA filters should be considered. These devices remove particles, significantly improving air quality. The Environmental Protection Agency (EPA) recommends maintaining ventilation for at least 48 hours after cleaning to ensure all airborne particles are removed.

Manage Waste Disposal Responsibly

Safe disposal of construction waste is a critical aspect of post-construction cleaning. A color-coded bin system for different types of waste should be implemented to streamline the recycling process.

For hazardous materials, local regulations must be strictly followed. The Resource Conservation and Recovery Act (RCRA) provides guidelines for the disposal of harmful substances. Certified disposal services should always be used for materials like asbestos or lead-based paint residues.

Prioritize Staff Training and Supervision

Comprehensive training is the cornerstone of safe post-construction cleaning. The Occupational Safety and Health Administration (OSHA) mandates that all workers receive training on hazard recognition and the proper use of safety equipment.

Regular refresher courses on the latest safety protocols and cleaning techniques should be provided to staff. This commitment to ongoing education can result in a significant reduction in workplace incidents.

Effective supervision is equally important. Experienced team leaders should oversee each cleaning project. These supervisors should conduct daily safety briefings, perform regular equipment checks, and ensure all team members adhere to safety protocols.

The complexity of post-construction cleaning operations often requires professional expertise. For those seeking reliable post-construction cleaning services in Seattle, Bumble Bee Cleaning Services offers a team of certified experts ready to tackle even the most challenging cleaning projects.

Final Thoughts

Post-construction cleaning presents numerous challenges and safety risks that require careful consideration and professional expertise. Construction site safety demands proper equipment, including personal protective gear and specialized cleaning tools, to mitigate these risks effectively. Implementing best practices such as thorough site assessments, effective ventilation strategies, and comprehensive staff training further enhances safety during cleaning operations.

Professional services offer significant advantages due to the complexity and potential dangers involved in post-construction cleaning. At Bumble Bee Cleaning Services, we prioritize safety in all our post-construction cleaning projects (our team of experts follows the latest safety protocols and cleaning techniques). We use eco-friendly products and state-of-the-art equipment to deliver exceptional results while minimizing environmental impact.

Our commitment to safety extends beyond our cleaning practices; we also provide our clients with valuable insights on maintaining a safe and clean environment. Property owners and contractors can trust that their spaces will be thoroughly cleaned and made safe for occupancy when they choose professional post-construction cleaning services. Bumble Bee Cleaning Services stands ready to tackle even the most challenging post-construction cleaning projects in Seattle and beyond.